The Effect of Plastic Injection Molding on Reducing Production Prices and Waste

The Effect of Plastic Injection Molding on Reducing Production Prices and Waste

Blog Article

Exploring the Applications of Plastic Injection Molding Across Industries

Plastic shot molding stands as a keystone of modern-day production, using exceptional adaptability throughout diverse sectors such as automotive, durable goods, health care, and electronics. Its capacity to generate complex, lightweight components successfully has not just enhanced item efficiency however has additionally added to cost-effectiveness. As industries increasingly focus on sustainability, the combination of innovative products provides both tests and possibilities. Comprehending how these advancements affect the landscape of manufacturing can disclose much regarding future trends and techniques (Plastic Injection Molding). What implications do these growths hold for markets moving ahead?

Automotive Market Innovations

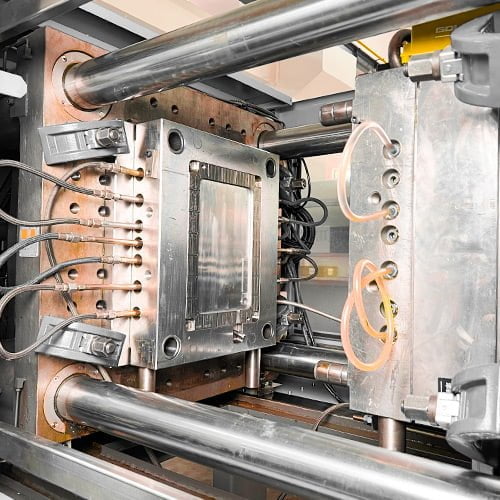

Changing the automobile landscape, plastic shot molding has actually emerged as a crucial innovation in the manufacturing of innovative vehicle parts. This manufacturing procedure permits the production of lightweight parts and complicated geometries, significantly contributing to automobile performance and performance.

In contemporary vehicle layout, plastic injection molding helps with the manufacturing of parts such as bumpers, dashboards, and interior trim pieces. These parts not just boost aesthetic appeal however likewise boost safety and security and functionality. For instance, the capability to mold complex layouts makes it possible for the assimilation of advanced features like airbag systems and electronic interfaces directly into the structural components.

As the automotive market remains to accept autonomous and electrical modern technologies, the duty of plastic injection molding will certainly end up being increasingly important. Its versatility and performance position it as a foundation modern technology for future developments in lorry design and manufacturing, driving innovations toward a much more lasting auto community.

Customer Item Manufacturing

The impact of plastic injection molding expands past the automotive industry, substantially affecting durable goods producing. This flexible strategy makes it possible for the manufacturing of a broad array of products, ranging from family things to detailed digital components. The ability to create complicated forms and styles with high accuracy enables suppliers to fulfill customer needs for both capability and aesthetic appeals.

Among the main advantages of plastic injection molding in consumer products is its effectiveness. The process allows for high-volume production, decreasing manufacturing costs and lead times. This efficiency is essential in a market characterized by rapidly changing customer choices and fads.

Eventually, plastic shot molding functions as a foundation in durable goods manufacturing, allowing the production of varied, premium items that accommodate evolving market demands while maximizing operational effectiveness. This flexibility guarantees its ongoing relevance in the competitive landscape of consumer products.

Health Care Applications

In the medical care field, plastic shot molding plays a vital role in the production of a large variety of clinical tools and parts. This production strategy enables the creation of precise and complex shapes needed for various applications, from surgical instruments to diagnostic equipment.

In addition, plastic injection molding enables the combination of functions such as texturing and facility geometries, which can improve the capability and individual experience of clinical devices. The procedure also supports rapid prototyping and short preparations, enabling producers to react rapidly to market requirements and technical developments.

Electronic Devices Production Methods

As industries progressively rely upon innovative manufacturing processes, plastic injection molding has likewise located substantial applications within electronics production. This method enables the reliable creation of intricate components that are vital for modern-day digital tools. From smart device coverings to motherboard, the accuracy and versatility of injection molding facilitate the production of top quality parts that meet rigorous industry standards.

Among the critical benefits of plastic shot molding in electronic devices is its capability to create complicated geometries that would be Learn More challenging to achieve with traditional production approaches. The fast cycle times connected with the process also enhance manufacturing performance, enabling producers to respond promptly to market needs.

Additionally, making use of specialized thermoplastics can improve the efficiency of digital elements. Materials such as polycarbonate and abdominal muscle use high toughness and outstanding electrical insulation, making them excellent for applications varying from ports to housing units.

In addition, injection molding supports the integration of several functions right into single components, lowering setting up time and prices. As modern technology proceeds to advancement, the role of plastic shot molding in electronics manufacturing is likely to increase, driving advancement and enhancing item performance throughout the industry.

Sustainability in Shot Molding

Sustainably incorporating techniques in injection molding significantly shapes the future of production, dealing with expanding environmental worries. As industries make every effort for eco-friendliness, the injection molding process adapts by implementing energy-efficient modern technologies and sustainable materials. Eco-friendly and recycled plastics are obtaining traction, minimizing dependence on nonrenewable fuel sources and lessening waste.

Additionally, developments in equipment and techniques objective to reduced power consumption during manufacturing. Electric injection molding makers are coming to be extra prevalent, providing substantial decreases in power use contrasted to traditional hydraulic systems. These devices not only save power however additionally boost accuracy and reduce cycle times, leading to lower operational costs.

Furthermore, business are embracing closed-loop systems to handle waste successfully. By reusing scrap product produced throughout the production procedure, they can lessen environmental news influence and advertise resource efficiency (Plastic Injection Molding). Implementing lasting techniques in injection molding not only satisfies governing demands yet additionally accommodates the boosting customer demand for environmentally responsible products

Verdict

Finally, plastic shot molding acts as a crucial manufacturing process throughout numerous markets, including automotive, durable goods, healthcare, and electronics. Its capacity to create complex and durable components successfully adds to enhanced item performance and cost decrease. Additionally, the continuous advancements in lasting methods and materials setting the industry to resolve environmental concerns properly. Therefore, plastic injection molding stays important for fulfilling the dynamic needs of modern markets while advertising sustainable manufacturing techniques.

Plastic shot molding stands as a cornerstone of contemporary production, supplying amazing adaptability across diverse markets such as vehicle, consumer goods, health care, and electronic devices.In modern automobile design, plastic injection molding promotes the production of parts such as bumpers, control panels, and indoor trim items.As industries increasingly depend on sophisticated production procedures, plastic shot molding has actually also found considerable applications within electronics production.In final thought, plastic shot molding offers as a crucial production procedure throughout different markets, consisting of vehicle, customer items, medical care, and electronic devices. Hence, plastic shot molding stays necessary for fulfilling the vibrant needs of contemporary markets while promoting sustainable manufacturing practices.

Report this page